WE ARE VDL KONINGS

DEVELOPMENT IS OUR PASSION, MANUFACTURING IS OUR DNA

WE ARE VDL KONINGS

DEVELOPMENT IS OUR PASSION, MANUFACTURING IS OUR DNA

WE ARE VDL KONINGS

DEVELOPMENT IS OUR PASSION, MANUFACTURING IS OUR DNA

WE ARE VDL KONINGS

DEVELOPMENT IS OUR PASSION, MANUFACTURING IS OUR DNA

WE ARE VDL KONINGS

DEVELOPMENT IS OUR PASSION, MANUFACTURING IS OUR DNA

WE ARE VDL KONINGS

DEVELOPMENT IS OUR PASSION, MANUFACTURING IS OUR DNA

VDL Konings is an efficient and flexible supplier for OEMs of complex parts and assembled products (components, modules, systems), which takes care of the product realization as a Tier 1 supplier. VDL Konings' customers are OEMs (end manufacturers) who consider outsourcing production as part of their strategy.

The machines, applications, adjustments and optimizations built by VDL Konings are used in various production processes of, among others, flexible web-guided materials (film, foil, foam), composites, rubber, rock wool and cars.

VDL Konings' expertise in innovative operational and R&D activities. From advanced production to groundbreaking developments.

Explore our opportunities! Our people will tell you what a day at VDL Konings looks like.

Join our New Facility journey!

As per December 2023, VDL Konings is working on creating a complete new building which results into a new manufacturing area of 18.500 m2 and a new office. Join our journey!

With +16.000 colleagues spread over 19 countries worldwide, VDL Group is one of the largest subcontractors in Hightech, Mobility, Energy, Infra and Food Technology.

WE ARE VDL KONINGS

DEVELOPMENT IS OUR PASSION, MANUFACTURING IS OUR DNA

WE ARE VDL KONINGS

DEVELOPMENT IS OUR PASSION, MANUFACTURING IS OUR DNA

WE ARE VDL KONINGS

DEVELOPMENT IS OUR PASSION, MANUFACTURING IS OUR DNA

WE ARE VDL KONINGS

DEVELOPMENT IS OUR PASSION, MANUFACTURING IS OUR DNA

WE ARE VDL KONINGS

DEVELOPMENT IS OUR PASSION, MANUFACTURING IS OUR DNA

WE ARE VDL KONINGS

DEVELOPMENT IS OUR PASSION, MANUFACTURING IS OUR DNA

The machines, applications, adjustments and optimizations built by VDL Konings are used in various production processes of, among others, flexible web-guided materials (film, foil, foam), composites, rubber, rock wool and cars.

VDL Konings is an efficient and flexible supplier for OEMs of complex parts and assembled products (components, modules, systems), which takes care of the product realization as a Tier 1 supplier. VDL Konings' customers are OEMs (end manufacturers) who consider outsourcing production as part of their strategy.

Explore our opportunities! Our people will tell you what a day at VDL Konings looks like.

VDL Konings celebrates 150 Year Anniversary

Join our New Facility journey!

As per December 2023, VDL Konings is working on creating a complete new building which results into a new manufacturing area of 18.500 m2 and a new office. Join our journey!

With +16.000 colleagues spread over 19 countries worldwide, VDL Group is one of the largest subcontractors in Hightech, Mobility, Energy, Infra and Food Technology.

About

VDL KONINGS

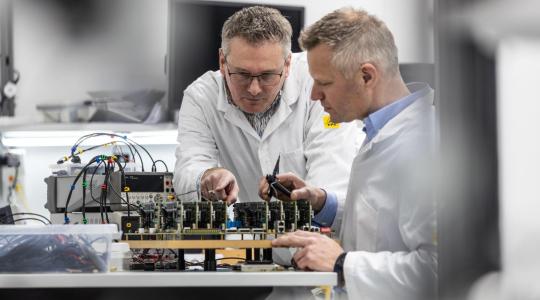

VDL Konings, part of the Dutch VDL concern, is a global design & manufacturing company, who supplies modules and complete systems for leading high-tech equipment companies (OEM’s). With our 150 years of experience, the unique combination of knowledge and high-quality craftsmanship under one roof, customers and partners can always expect a solution, whatever the question. We are constantly innovating to help customers differentiate themselves with new ideas for products that improve our daily lives. Our expertise in various technologies and collaborations in different markets enables us to develop advanced high-tech systems. From mechatronics to optics, our multidisciplinary teams create customized, integrated solutions that address unique customer needs. This involvement extends across the entire product life cycle, making VDL Konings unique. From analysis to hands-on production work, we provide a total experience.

Certfications

ISO 9001:2015 ISO 13485-2016 ISO 3834-2 EWF ISO 3834-2 IIW EN 1090

Our company profile

VDL Konings

Within VDL Konings, we focus on two main domains Systems & Modules and Turnkey Projects.

For Systems & Modules, we co-develop and manufacture systems for the markets: Medical and Semiconductor. Each of these markets presents unique characteristics and challenges. VDL Konings plays a distinctive role in addressing these challenges through the development and product realization of cutting-edge products, machines, parts, and services, offering comprehensive solutions tailored to the specific needs of each market segment.

For Turnkey Projects, we are focussing on the development and realization of production processes. Based on our stage gate project approach, we develop production lines incorporating Mechananical, Electrical and Software competences. The main applications we are working on are film, foam, composites, rubber, rock wool and automotive assemblies.

The direct r&d activities of

VDL KONINGS

VDL Konings distinguishes itself in its Research & Development activities by utilizing a wide range of technical disciplines. These include Mechanical Engineering, Electrical Engineering, Software Engineering, AI Engineering (currently still in development), and New Product Introduction Engineering.

Within Mechanical Engineering, the focus is on refining and optimizing mechanical designs and production processes. Electrical Engineering concentrates on the development of high-quality electrical systems, while Software Engineering deals with the design and optimization of software applications. In line with the rise of artificial intelligence, VDL Konings is also investing in AI Engineering. Additionally, New Product Introduction Engineering involves the streamlined introduction of new products to the market.

These diverse technical disciplines collaborate to strengthen VDL Konings' R&D efforts, with innovation and technological leadership at the forefront.

The direct operational activities of

VDL KONINGS

VDL Konings performs various operational activities to produce high-quality products. These activities includes:

- Welding (manual and robot) for joining metal components;

- Machining to create precise shapes;

- Measuring for quality control;

- Painting for a durable finish;

- Assembly (mechanical and electrical) of various parts;

- Testing to ensure performance;

- Packaging for shipment and protection during transport.

Stories from our

EMPLOYEES

VDL Groep

Latest NEWS

VDL Groep strengthens its position in electro ...

VDL De Meeuw to build 286 modular homes for A ...

Production of military equipment starts at VD ...

VDL Bus Group presents new coach at Busworld

The new VDL Bus Group launches VDL Futura 3 a ...

First six months at VDL Groep: Stable turnove ...

VDL Groep extends sponsorship contracts with ...

VDL Hydrogen Systems and Battolyser Systems j ...

Ministry of Defence and VDL taking concrete s ...

Found what you were looking for?

No? Then continue your search here, or contact VDL Konings directly.